Steel cord (fabric) core conveyor belt vulcanizing production line

Full line, steel cord conveyor belt production line

Tension device, integrated heavy clamp tension station, split tension station

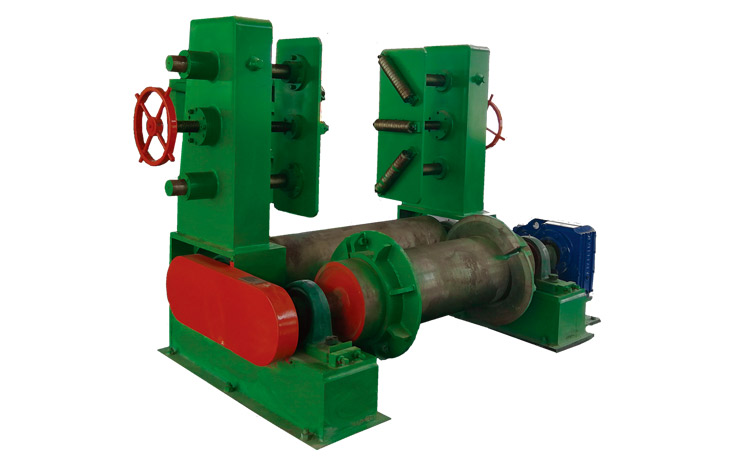

Front holding stretching device

Multifunctional belt drawing machine, five-roll drawing machine, multifunctional

Flat vulcanized production line for fabric core conveyer belt

Rubber conveyor belt detection and repair vulcanization unit

An Hubei flat plate vulcanizing machine

Column type flatbed vulcanizing machine

Frame type hot press plate vulcanizing machine

Packaging coiler

| Steel cord conveyor belt(fabric) flat vulcanization production line Technical parameters / name | ||||||||

| perfermance parameters | 1200X10000 | 1400X10000 |

1800X10000 (12600) |

2000X10000 | 2200X10000 |

2400X10000 (10600) |

2600X10600 | 2700X15600 |

| Nominal mounding force MN | 48 | 56 | 72/90.72 | 80 | 88 | 108/114.48 | 124.02 | 176.9 |

| Hot plate specifications(L*W)mm | 1200X10000 | 1400X10000 |

1800X10000 (12600) |

2000X10000 | 2200X10000 |

2400X10000 (10600) |

2600X10600 | 2700X15600 |

| Hot plate unit pressureMPa | 4 | 4 | 4 | 4 | 4 | 4.5 | 4.5 | 4.2 |

| Cylinder diameter/mm | 420 | 500 | 600 | 600 | 600 | 650 | 650 | 650 |

| Number of cylinders/支 | 18 | 16 | 16/20 | 16 | 16 | 16/18 | 18 | 24 |

| Clamping force/KN | 700 | 900 | 1200 | 1300 | 1500 | 1700 | 1800 | 2000 |

| Tensile force/KN | 350 | 450 | 600 | 650 | 750 | 850 | 900 | 1000 |

|

Maximum initial tension of a single wire rope/N |

400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

|

Single wire rope tension adjustment range/N |

800-3000 | 800-3000 | 800-3000 | 800-3000 | 800-3000 | 800-5300 | 800-5300 | 800-5300 |

|

1200X12600X2 Batching label specification(2 sets)

|

|||||

|

Number

|

Model

|

Name

|

Quantity

|

Material

|

Remarks

|

|

1

|

GB/T799-1998

|

Anchor bolt M20X500

|

20

|

Level 4.8

|

|

|

2

|

GB/T5780-2000

|

bolt M12X50

|

16

|

Level 4.8

|

|

|

3

|

GB/T41-2000

|

screw nut M12

|

8

|

Level 5

|

|

|

4

|

GB/T41-2000

|

screw nut M20

|

20

|

Level 5

|

|

|

5

|

GB/T95-2002

|

washer12

|

24

|

100HV

|

|

|

6

|

GB/T95-2002

|

washer20

|

20

|

100HV

|

|

|

7

|

STO40-50 VT4 45X45U

|

Safety chuck (passive end)

|

2

|

Finished product

|

Chaoyang Sanchuang

|

|

8

|

STW40-50 VT4 45X45U+M-8/B(Powered)

|

Safety chuck (active end)

|

2

|

Finished product

|

Sprocket pitch 19.05 teeth 42

|

|

9

|

GB/T1243-1997

|

Chain (12A) 105 saves 2m

|

2

|

Finished product

|

Pitch 19.05

|

|

10

|

TK58-Y2.2-4P-15.22-M1-I-A

|

Spiral bevel gear reducer

|

2

|

Finished product

|

Zhejiang Tongli

|

|

11

|

GB/T37-1988

|

T-bolt M12X60

|

8

|

Level 8.8

|

|

|

Fiction:Yang Chengren Date:Jan.10th 2018 Review: Date:

|

|||||

|

1200X12600X2 batcher plus parts details(two sets)

|

|||||

|

Number

|

Drawing number

|

Name

|

Quantity

|

Material

|

Remarks

|

|

1

|

TS1802-09-00

|

Rolling device (left drive)

|

2

|

Component

|

|

|

2

|

TS1711-2-1-00

|

Stand

|

2

|

Weldment

|

|

|

3

|

TS1711-2-1-1

|

Bottom plate

|

2

|

Q235-A

|

|

|

4

|

TS1711-2-1-2

|

Rectangular square tube

|

4

|

Q235-A

|

|

|

5

|

TS1711(左)-2-2-00

|

Bracket (left drive)

|

2

|

Weldment

|

|

|

6

|

TS1711-2-2-1

|

Bottom plate

|

2

|

Component

|

|

|

7

|

TS1802-09-01

|

45 square steel

|

2

|

45

|

|

|

8

|

TS1711-2-3-00

|

safety cover

|

2

|

Q235-A

|

|

|

9

|

TSG1396-01

|

Reducer sprocket

|

2

|

45

|

|

|

10

|

TS1415-04-02

|

T-slot plate

|

4

|

Q235-A

|

|

|

Fiction:Yang Chengren Date: Jan.10th 2018 Reivew: Date:

|

|||||